8-9F, Blding A, Nanbiantou S&T Park, Tianyang 2nd Road, Oriental Community, Songgang Street, Bao'an District, Shenzhen 518105, Guangdong, China

Telephone:+86-755-23005669

Certified Medical Adapters: How to Match Your Device for Safety and Compliance

In the fast-evolving world of healthcare technology, ensuring patient safety and regulatory compliance starts with something as fundamental as your device’s power supply. Medical-grade adapters aren’t just accessories—they’re critical components that bridge innovation and safety. But how do you choose the right one? The answer lies in understanding standards like IEC 60601 and the critical differences between MOOP and MOPP. Let’s break it down—and introduce you to Merryking, a trusted partner for medical power solutions.

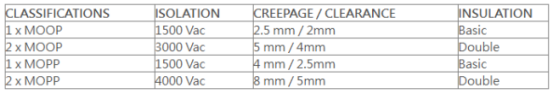

Under the IEC 60601-1 standard, medical devices are categorized based on who interacts with them: operators (healthcare staff) or patients. These distinctions define the safety requirements for power adapters.

MOOP (Means of Operator Protection)

MOOP safeguards operators—think nurses, technicians, or clinicians—who handle medical equipment. Since operators are trained to recognize risks (e.g., minor electrical shocks), MOOP requirements are less stringent. Single-layer insulation and lower creepage/clearance distances (e.g., 3mm) are typical. For example, an adapter for a handheld ultrasound device used by a technician may only need MOOP compliance.

MOPP (Means of Patient Protection)

MOPP applies when patients are directly connected to devices, such as ECG monitors, ventilators, or infusion pumps. Here, the stakes are higher: patients may be unconscious, immobilized, or connected via invasive leads. MOPP demands dual insulation, larger creepage/clearance distances (e.g., 8mm), and reinforced isolation to block leakage currents. Devices requiring MOPP must also pass rigorous dielectric tests (e.g., 4,000V AC vs. MOOP’s 1,500V AC).

Key Takeaway: If your device touches a patient, MOPP compliance is non-negotiable. Choosing the wrong protection level risks safety breaches, regulatory rejection, or legal liabilities.

Navigating compliance can feel overwhelming, but partnering with an experienced supplier simplifies the process. Merryking, as a leader in the field of medical-grade power adapters, is trusted by giants such as Medtronic. Here’s why they stand out:

Merryking’s 1-24W adapters are engineered to meet IEC 60601-1 standards, supporting both MOOP and MOPP applications. Whether your device is a portable glucose monitor or a bedside dialysis machine, these adapters deliver:

Reliable Performance: Stable power output for sensitive medical electronics.

Compact Design: Space-saving form factors for portable or embedded systems.

Enhanced Safety: Built-in protections against over-voltage, short circuits, and overheating.

Unlike many suppliers, Merryking owns state-of-the-art manufacturing facilities and employs a dedicated technical team. This ensures:

Quality Assurance: Strict in-house testing for every batch.

Customization: Tailored solutions for connectors, shielding, or form factors.

Speed: Rapid prototyping and production turnaround.

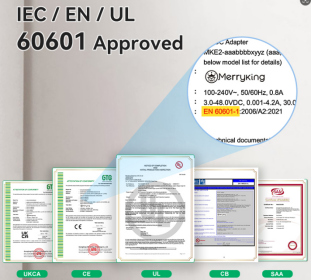

Merryking’s adapters come pre-certified for seamless market access:

UL/cUL: Compliant with North America’s strict safety norms.

CE/UKCA: Meets EU and UK post-Brexit regulations.

FCC: Ensures electromagnetic compatibility (EMC) to avoid interference.

SAA: Approved for Australia’s rigorous standards.

These certifications eliminate guesswork, accelerating your path to approvals in target regions.

With years of experience serving clients like Medtronic, Merryking understands the unique challenges of medical device design. Their adapters are tested in real-world scenarios, from hospital settings to remote care environments, ensuring:

Durability: Resistance to moisture, chemicals, and mechanical stress.

Flexibility: Customizable connectors, input voltages, and shielding for noise-sensitive applications.

Scalability: Solutions tailored for low- or high-volume production.

Medical device manufacturers face immense pressure to innovate while adhering to ever-changing regulations. A subpar adapter can derail timelines, damage reputations, or—worst of all—endanger lives. Merryking mitigates these risks by offering:

Compliance Confidence: Adapters pre-tested for IEC 60601, MOOP/MOPP, and regional certifications.

Technical Collaboration: Expert guidance on thermal management, EMC, and risk assessments.

Future-Proofing: Solutions adaptable to emerging technologies like IoT-enabled devices.

Matching your medical device with the right adapter isn’t just about specs—it’s about trust. By understanding MOOP/MOPP requirements and partnering with Merryking, you gain access to IEC 60601-certified 24W adapters backed by global certifications and proven industry expertise. Whether you’re designing the next breakthrough in patient monitoring or upgrading existing equipment, Merryking ensures your power supply is as reliable and safe as your innovation.

Ready to streamline compliance and focus on what matters most—your patients? Let Merryking power your journey.