8-9F, Blding A, Nanbiantou S&T Park, Tianyang 2nd Road, Oriental Community, Songgang Street, Bao'an District, Shenzhen 518105, Guangdong, China

Telephone:+86-755-23005669

As a procurement manager, sourcing components like AC-DC power adapters is a critical task that balances cost, quality, reliability, and supply chain stability. Based on my extensive experience in electronics procurement, a poor adapter choice can lead to product failures, safety incidents, and significant brand reputation damage. I recall a project where initial cost-saving on non-certified adapters resulted in a costly recall and redesign. This underscores that buying AC DC power adapters for procurement is not merely a transactional purchase but a strategic technical decision.

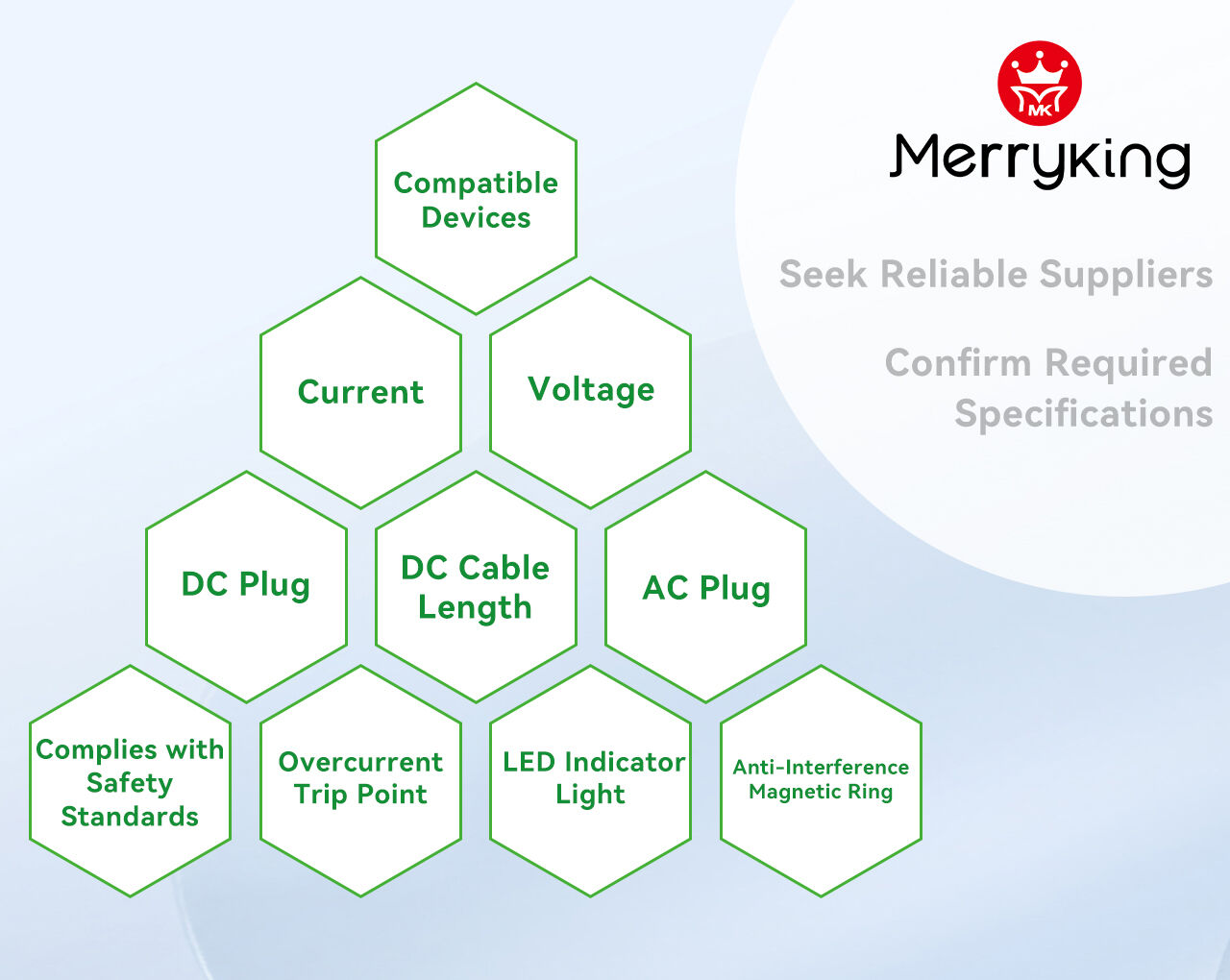

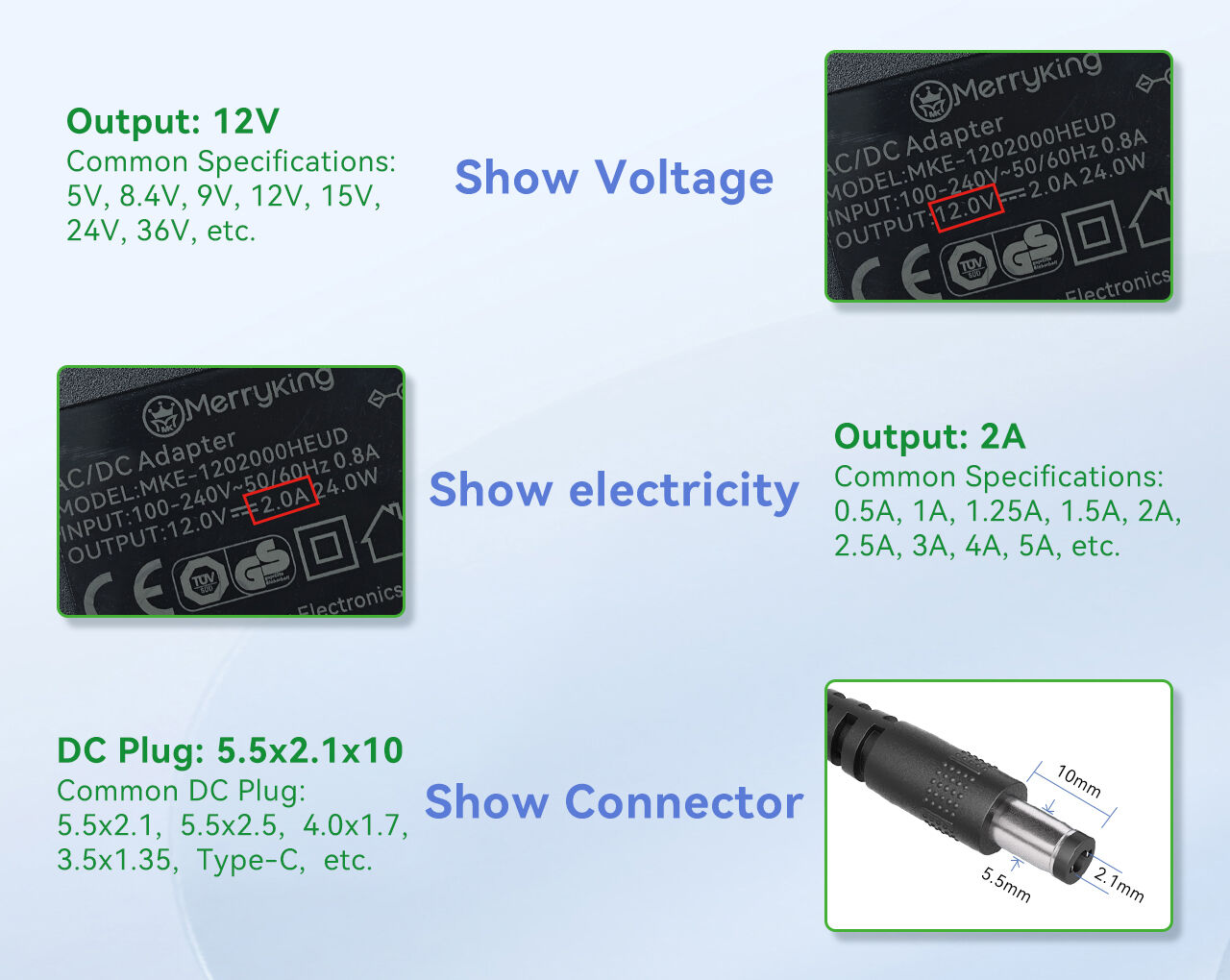

Your primary expertise must lie in understanding key specifications. The output voltage (V) and current (A) are just the starting point. Procurement managers must delve into regulation (how stable the output is under load variations), ripple & noise (electrical interference that can harm sensitive devices), and efficiency ratings (look for Level VI or higher, impacting energy costs and heat). For instance, adapters from Merryking are engineered with high precision, offering tight voltage regulation and low ripple, which is crucial for powering modern electronics like security cameras, wireless routers, or POS systems reliably. Ensuring the adapter’s specifications not only match but exceed the minimum requirements of your device provides a safety margin for peak performance.

Authority in this domain is defined by rigorous international standards. Never compromise on safety certifications. Authoritative bodies like UL, CE, TUV, and FCC set the benchmarks. A certified adapter, such as those from Merryking which carry marks like UL, CE, and RoHS, has undergone stringent testing for electrical safety, fire resistance, and electromagnetic compatibility. These certifications are your legal and ethical shield. They are not just stickers; they represent compliance with directives like the Low Voltage Directive (LVD) and Radio Equipment Directive (RED) in the EU. Sourcing uncertified adapters exposes your company to liability, safety hazards, and market access barriers.

Expert procurement analysis requires evaluating the Total Cost of Ownership, not just the purchase price. A cheaper, low-quality adapter may have a higher failure rate, leading to increased costs in customer support, returns, warranty claims, and logistics. Furthermore, inefficient adapters consume more grid power, adding to the operational energy costs of your end-users. Investing in reliable, high-efficiency adapters from a reputable supplier like Merryking translates to lower long-term costs, enhanced customer satisfaction, and reduced environmental impact due to better energy utilization and longevity.

Practical experience teaches that physical and electrical compatibility is paramount. Beyond the electrical specs, managers must verify the connector type (barrel jack, USB-C, etc.), polarity (center-positive/negative), pin diameter, and cable length. A mismatch renders the adapter useless. Furthermore, consider the mechanical design—does it need to fit into a compact space? Is it for desktop use or a wall plug? Merryking’s portfolio includes a wide range of form factors, from compact wall plugs to desktop models with interchangeable plug heads, offering the flexibility needed for global product deployments and diverse user environments.

Trustworthiness is built on a supplier's track record and transparency. A credible manufacturer doesn’t just sell a product; they offer engineering support, consistent quality control, and stable supply chains. Evaluate potential partners on their R&D capability, in-house testing facilities, quality management systems (like ISO 9001), and post-sales support. For example, a supplier with deep expertise can provide custom solutions, such as specific cable lengths or OEM branding, which Merryking offers, ensuring the adapter integrates seamlessly into your final product package. Always request audit reports or sample batches for independent verification before large-scale buying AC DC power adapters for procurement.

In conclusion, the procurement process for power adapters demands a holistic, informed approach. It intertwines deep technical knowledge with strategic supply chain management. By prioritizing certified quality, true TCO, precise compatibility, and supplier partnership over the lowest bid, procurement managers secure a critical component that powers both their products and their company’s reputation in the market. Partnering with established, technically proficient manufacturers provides the assurance needed for successful, risk-mitigated sourcing.

To translate this knowledge into action, here is a practical checklist: 1. Verify all required safety certifications (UL, CE, etc.) are authentic and current. 2. Match and slightly overspec the electrical output, paying attention to ripple and efficiency ratings. 3. Physically test samples for compatibility, thermal performance, and output stability under load. 4. Calculate TCO, factoring in failure rates and efficiency. 5. Vet the supplier’s manufacturing capacity, quality controls, and lead time reliability. 6. Plan for logistics, including packaging, labeling, and minimum order quantities (MOQs). This disciplined process is fundamental to buying AC DC power adapters for procurement effectively.