8-9F, Blding A, Nanbiantou S&T Park, Tianyang 2nd Road, Oriental Community, Songgang Street, Bao'an District, Shenzhen 518105, Guangdong, China

Telephone:+86-755-23005669

Smartphones, laptops and other modern gadgets need consistent voltage control to avoid data loss and damage to components over time. According to market reports from 2025, consumer electronics made up around 51.6 percent of the worldwide switching power supply market, which really shows how dependent these products are on getting just the right amount of power. Even minor voltage changes of plus or minus 5% can shorten lithium ion batteries' life expectancy by about 22%. That's why manufacturers who produce large quantities of devices must work with suppliers who know their way around surge protectors and noise filters. Getting this part right makes all the difference between a product that lasts years and one that starts acting up after just a few months.

The best power supply manufacturers manage to hit AC-DC conversion rates between 85% and 94%, which means their products generate far less heat inside all sorts of equipment ranging from hospital monitoring systems down to smart home devices connected to the internet. They've developed really sophisticated circuitry along with special transformers that keep ripple voltage below 3%, something absolutely necessary for those high precision machines used in factories and data centers where even small fluctuations can cause problems. What makes these power adapter so versatile is their ability to work across a wide range of input voltages from 90 volts up to 264 volts AC. This feature allows electronic companies to ship their products anywhere around the world without worrying about compatibility issues with local electrical standards.

Top manufacturers are rolling out 65 watt GaN adapters that fit within just 40 cubic millimeters space, which makes them about 30 percent tinier compared to older silicon versions. The shrinking size helps create thinner laptop designs and enables quicker charging for USB-C devices too. Plus these new adapters come equipped with built-in safeguards against overheating plus smart current management features. We're seeing this trend match up nicely with what the market wants right now there's been around a 27% yearly increase in need for power solutions below 100 watts lately. Wearable tech gadgets and those fancy augmented reality virtual reality headsets are really pushing this demand forward.

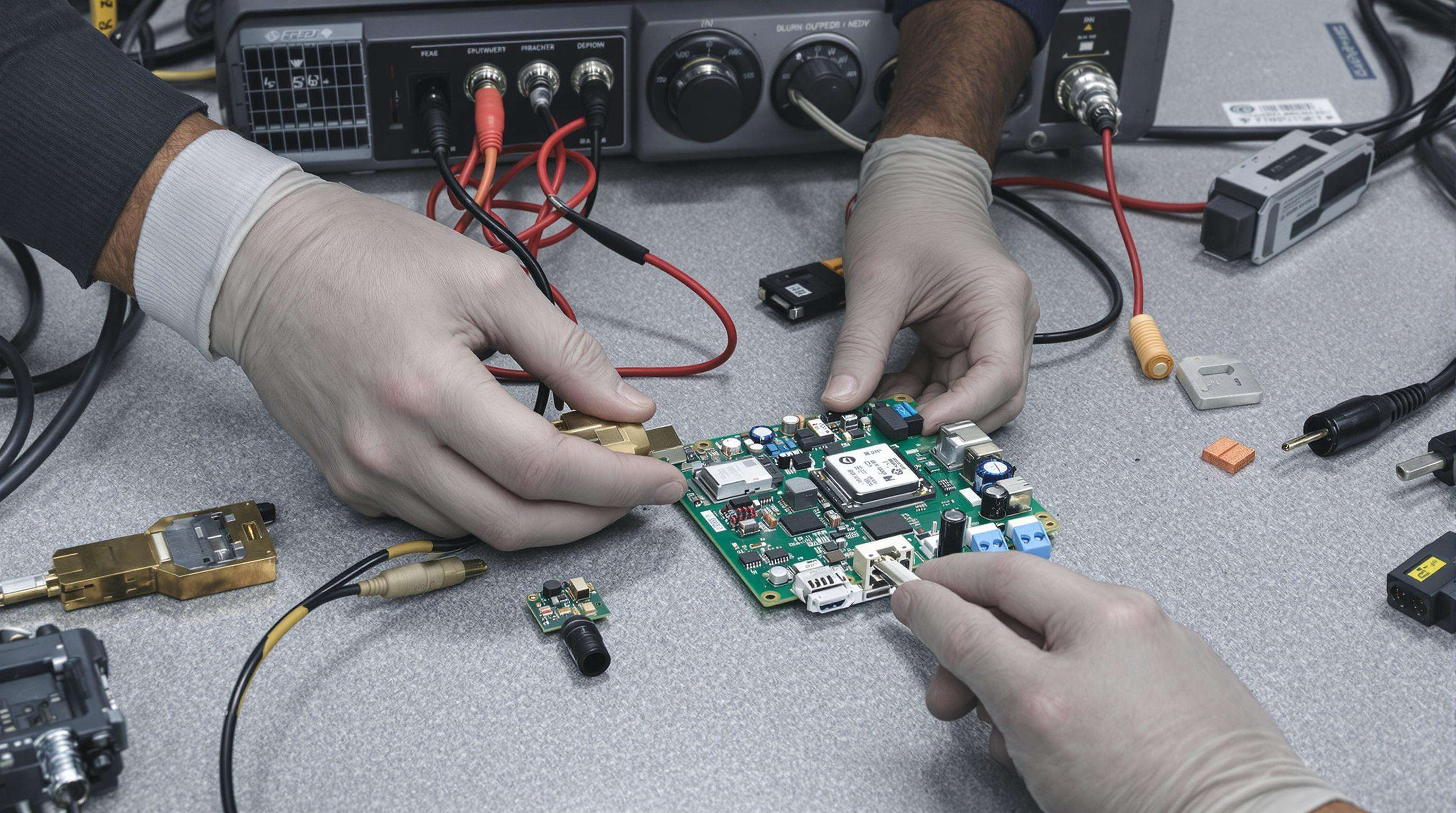

What really sets suppliers apart is their ability to handle those tricky design challenges in industrial robotics and medical equipment, areas where regular off-the-shelf adapters just don't cut it. The specs here are pretty tough stuff actually, requiring voltage regulation that stays within about 1% tolerance plus solid fault protection against all sorts of electrical issues. According to some recent industry research from last year, most manufacturers (around two thirds) look for partners who've already shown they can manage heat dissipation problems and deal with electromagnetic interference properly. Makes sense when you think about how critical these components are in sensitive environments like hospitals or manufacturing floors.

The latest GaN and SiC semiconductor tech is really pushing the envelope when it comes to efficiency standards, allowing EV charging stations to pack as much as 100 watts per cubic inch of power density. Looking at data centers now, those fancy 48V DC setups running at around 94% efficiency cut down on cooling expenses quite a bit actually saving somewhere close to $3,800 each year for every server rack. Meanwhile industrial IoT applications are starting to depend heavily on these rugged IP67 rated power adapters that can handle pretty brutal conditions from freezing cold at minus 40 degrees Celsius all the way up to scorching heat reaching 85 degrees Celsius.

A robotics manufacturer collaborated with its supplier to develop a 95%-efficient 24V/10A module with less than 0.5% ripple voltage. The passive cooling design eliminated 20% of energy losses typically caused by forced-air systems, enabling continuous operation in automotive assembly lines.

The modular power adapter market is projected to grow at 11.2% CAGR through 2030, fueled by renewable energy integration and edge computing. Suppliers using field-upgradable designs report 40% faster customization cycles. Scalable 5–60W building-block modules now support parallel configurations for high-voltage applications up to 400V DC.

When it comes to certifications, names like UL (Underwriters Labs), CE (European Conformity), and IEC (International Electrotechnical Commission) really matter because they show suppliers actually follow safety standards and performance requirements. For instance, adapters that get UL approval have to survive thousands upon thousands of operation cycles while being subjected to harsh conditions that simulate real world wear and tear. And let's not forget the bottom line impact either. Last year alone, products that failed to meet these standards led to around 740 thousand dollars worth of recalls according to Ponemon Institute research. That kind of money loss underscores why getting proper certification isn't just about paperwork but represents serious business risk management.

Real green claims usually come with some sort of third party certification behind them, think EPEAT or TCO Certified stuff that actually checks how energy efficient something is and whether it can be recycled properly. The companies worth their salt will tell customers exactly what their carbon footprint looks like and often mix around 20 to 30 percent post consumer recycled plastic into the actual product casing. We saw some pretty shocking numbers back in 2024 too when testing showed nearly two thirds of products labeled as eco friendly didn't pass basic toxicity checks. That's why folks really need to look for those verifications and demand transparency from manufacturers instead of just taking marketing at face value.

Leading suppliers offer real-time shipment tracking, with 84% of electronics brands prioritizing end-to-end logistics visibility (Electronics Sourcing Report 2024). Custom AC-DC adapters with lead times under 30 days are now standard in fast-moving sectors like IoT and medical devices, where delays can cost over $15k/day in halted production.

Top suppliers provide:

This support infrastructure minimizes downtime, especially in data centers and EV charging systems where redundancy failures can incur six-figure losses.

Market forecasts suggest the worldwide power adapter sector will expand at around 4 percent annually until 2030, eventually hitting nearly nine billion dollars according to recent market analysis reports. Several factors are fueling this expansion including the rollout of fifth generation networks, advancements in edge computing technology, and growing automation across manufacturing sectors. We're also seeing rising interest from companies developing intelligent robots powered by artificial intelligence as well as connected devices throughout homes and offices, which creates greater need for custom made AC to DC converters and other specialized power solutions. Those manufacturers who focus their research efforts on creating more efficient products stand to grab almost 40 percent of emerging opportunities, especially in areas where digital transformation is happening fastest right now.

The rise of Gallium Nitride (GaN) and Silicon Carbide (SiC) is really pushing boundaries when it comes to making those small but powerful adapters we see everywhere nowadays. Looking at the numbers, around 45 percent of all new industrial systems being built today actually have modular designs. These setups allow for different voltage levels which is super important for places like data centers and factories running automation gear. Speaking of trends, the 65 watt plus category has become something of a hotbed for innovation lately. Industry reports show this segment growing at about 7.2% year over year according to Power Supply Device Market stats from 2025. Makes sense too considering how big hyperscale computing operations need their power solutions to handle heat fluctuations better than ever before.

Electric vehicle charging infrastructure is the fastest-growing segment, with global adapter demand expected to triple by 2027. Suppliers integrating solar-compatible MPPT controllers and bi-directional converters are gaining ground in renewable energy. Edge computing requires ruggedized, temperature-resilient power supplies, creating a $2.1 billion niche market by 2030.

Power adapters provide consistent voltage control, preventing data loss and component damage, thus prolonging the lifespan of electronic devices.

Certifications such as UL, CE, and IEC ensure power adapters meet safety and performance standards, reducing risks associated with product recalls and faulty devices.

Modern power adapters have evolved with innovations such as GaN and SiC technology, enabling smaller sizes, increased efficiency, and better compatibility with a range of devices.